Tealight candle,Tea light candle,Wax tealight candle,Paraffin wax tealight,cheap price white tealight candle Meichen(Hebei) Technology.,Ltd , https://www.mchenhome.com

Laser technology has revolutionized the sensor industry by offering advanced processing solutions that meet the high demands of modern sensors. According to the national standard GB7665-87, a sensor is defined as a device capable of detecting and converting physical or chemical information into an available output signal based on a specific law. As a critical testing tool, sensors must operate reliably in harsh environments, maintaining high stability and precision. Traditional manufacturing techniques have struggled to meet these requirements, leading to challenges in sensor production. However, the emergence of laser technology has brought significant improvements and new opportunities to the industry.

Laser marking, for instance, provides an efficient and precise method for labeling sensors. The process involves a high-energy continuous laser beam generated by a laser source. When this beam interacts with the material surface, it excites atoms from their ground state to a higher energy level. These excited atoms quickly return to their original state, releasing energy in the form of photons. This energy causes localized melting or vaporization of the material, resulting in a permanent and highly visible mark. Laser marking is not only accurate but also cost-effective, with marks that are difficult to remove, significantly improving product traceability.

Laser welding is another key application in sensor manufacturing. Using a pulsed laser with a wavelength of 1064nm, the laser beam is expanded, reflected, and focused onto the workpiece. The heat generated through conduction melts the material, forming a controlled molten pool. Precise control over parameters such as pulse width, energy, peak power, and repetition frequency ensures strong, clean welds. This technique is particularly useful for sealing metal casings of sensors, offering advantages like minimal heat-affected zones, high efficiency, and low costs.

In addition, laser trimming plays a crucial role in adjusting resistor values with high accuracy. A computer-controlled laser system directs high-energy pulses onto resistive materials. Upon absorbing the laser energy, the material rapidly heats up and evaporates, creating small spots or slits. By carefully controlling the shape and length of these cuts, resistors can be precisely adjusted to their desired nominal values. This process offers excellent repeatability, speed, and automation potential, making it ideal for mass production.

Overall, laser technology has transformed the sensor manufacturing landscape, enabling higher precision, reliability, and efficiency. It has become an essential tool for overcoming the limitations of traditional methods and ensuring the continued advancement of sensor technology.

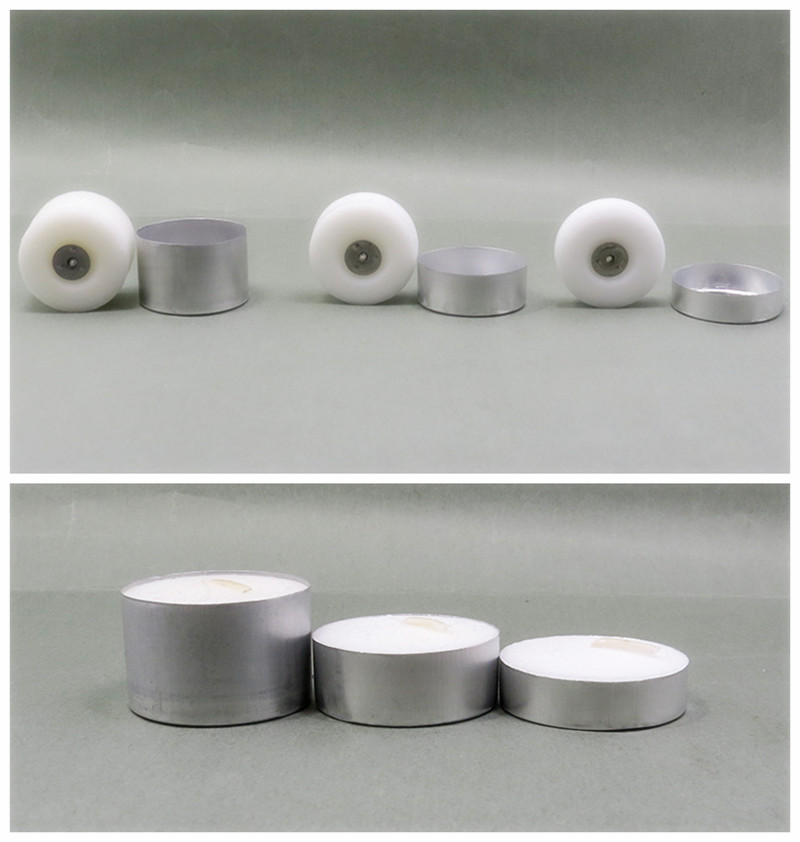

Wax tealight candle

Material:Paraffin wax ,Soy Wax, Coconut Wax

Weight:8g to 23g

Package:50pcs/bag,100pcs/bag

Burning time:0.5hrs-8hrs

Color:white, red, blue, yellow, green etc