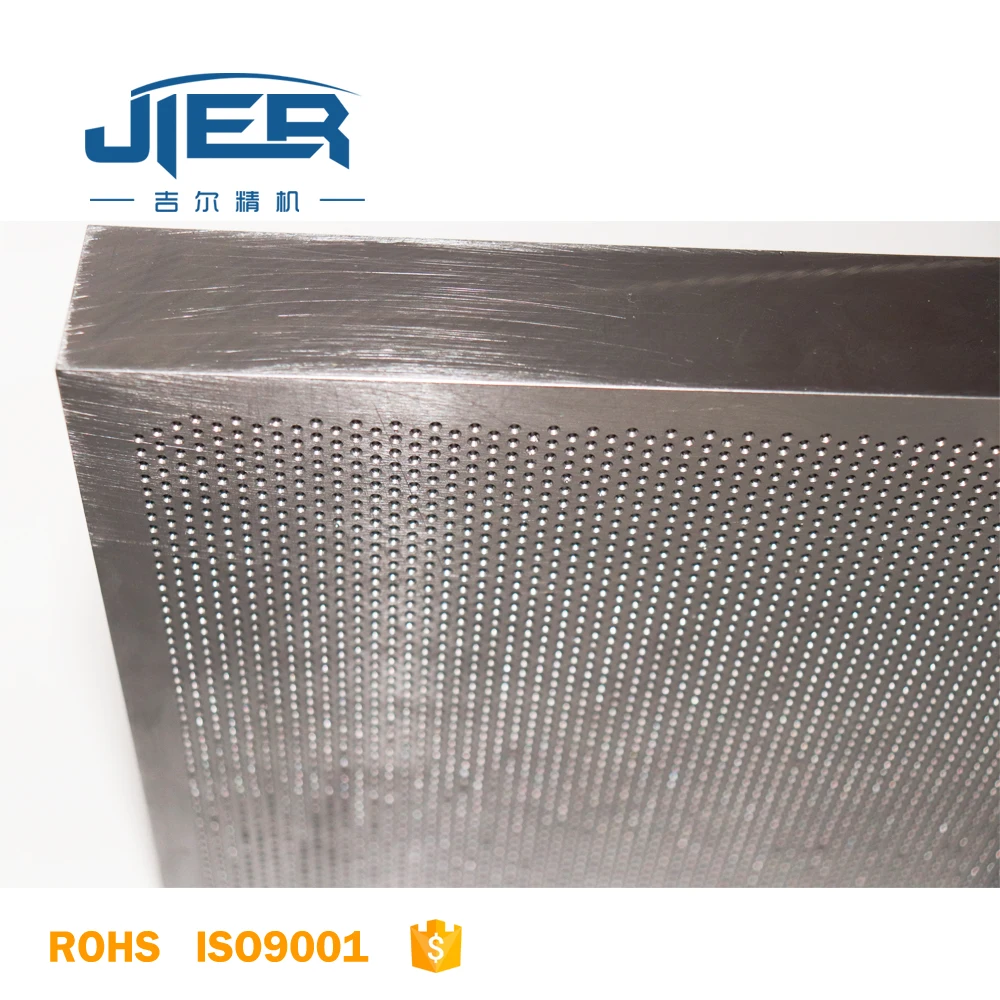

micro hole machining

micro hole machining ,micro-hole processing ,cnc drilling Changzhou Jier Precision Machinery Manufacturing Co., Ltd. , https://www.jier-spinneret.com

2. Size: Customized

Delivery Details : 30 working days

Q: Are you trading company or manufacturer ?

Q: Do you provide samples ? is it free or extra ?

Q: What is your terms of payment ?

If you have another question, please feel free to contact us.

Tianjin Valve Manufacturers: 12 Points for Installation of Flange Butterfly Valves The rotary center of the butterfly plate (ie, the center of the valve stem) is located on the cross section of the center line of the valve body and the sealing surface of the butterfly plate. The seat is made of synthetic rubber. When closing, the outer sealing surface of the butterfly plate presses the synthetic rubber valve seat, so that the valve seat is elastically deformed, thereby forming an elastic force as the seal of the butterfly valve to ensure the sealing ratio. Flange butterfly valve seal structure using PTFE, synthetic rubber composite valve seat, which is characterized by the elasticity of the valve is still provided by the synthetic rubber and the use of PTFE low friction coefficient, easy to wear, not easy to aging and other characteristics, so that The life of the butterfly valve is improved. Flange butterfly valve has the same sealing principle and structural features as common midline butterfly valves. Flange butterfly valve sealing structure uses PTFE, synthetic rubber and phenolic resin to form a composite valve seat, so that the valve seat is more flexible at the same time. At the same time, the butterfly plate is coated with PTFE, so that the butterfly plate has a strong anti-corrosion performance. 1. Before the flange butterfly valve is installed, check all the parts of the pneumatic butterfly valve without missing. The model is correct. Check the valve body for no debris. The solenoid valve and the silencer have no obstruction. 2. Place both the valve and the cylinder in the closed state. 3, the cylinder hit the valve, (installation direction and the valve body can be parallel or vertical can be), and see if the screw hole is aligned, there will be no big deviation, if there is a little deviation, the cylinder body can be rotated a little Then tighten the screws. 4, after installation, the pneumatic butterfly valve debugging (normally, the supply pressure is 0.4 ~ 0.6MPa), debugging operation must be manually operated solenoid valve opening and closing (the solenoid valve solenoid valve after the loss of electricity can be effective), Observe the opening and closing of the pneumatic butterfly valve. If during commissioning, the valve is found to be a bit difficult at the beginning of the opening and closing process, then after normal, you need to reduce the cylinder stroke (adjust the adjustment screw at both ends of the cylinder at the same time, adjust the valve to the open position , then turn the air source off and then adjust) until the valve opens and closes smoothly and closes without leakage. It should also be noted that the adjustable silencer can regulate the opening and closing speed of the valve, but it cannot be adjusted too small, otherwise it may cause the valve to not move. 5, hair should be kept dry before installation, not open storage. 6, Tianjin valve manufacturers remind everyone to check the pipeline before installing the butterfly valve, to ensure that there is no foreign matter such as welding slag. 7, butterfly valve body manual opening and closing resistance is moderate, the butterfly valve torque and the selected actuator match. 8. The butterfly valve connection flange has the correct specifications, and the pipe flange flange and butterfly valve flange standards are in agreement. It is recommended to use special flanges for butterfly valves. Welded flanges must not be used. 9. Make sure that the flange welding is correct. After the butterfly valve is installed, do not weld the flange again to avoid scalding the rubber parts. 10. The aligned pipe flange must be aligned and centered with the inserted butterfly valve. 11. Install all the flange bolts and tighten them by hand to confirm that the butterfly valve and the flange are already aligned. Carefully open and close the butterfly valve to ensure flexible opening and closing. 12. Fully open the valve and use the spanner to tighten the bolts in diagonal order. No washers are required. Do not tighten the bolt too tightly to prevent the valve ring from being seriously deformed and the opening and closing torque is too large. This article editor: Tianjin valve manufacturers Dan Ruisi valve

Product Description

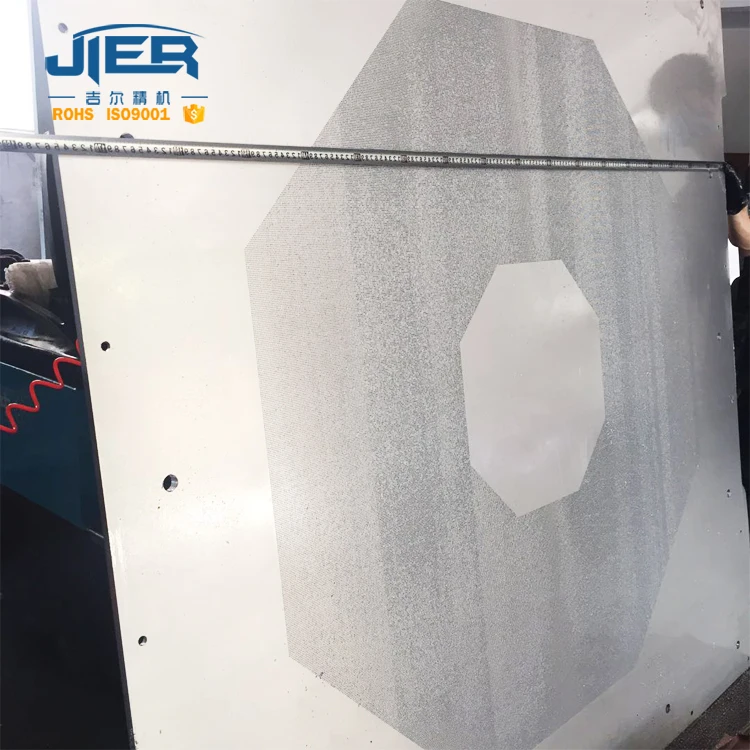

Spandex Nozzle for Spandex yarn Making Medical Mask Earloop Extrusion Nozzle

1. Grade: SUS431/SUS630

3.For Spandex Yarn 20D 40D 70D 90D 140D

drilling machiningProduct Name

drilling machining

Material

Stainless Steel

Grade

SUS630/SUS431/SUS316

Smoothness of Surface

Mirror

Brand

JIER

Ude

Extrusion Machine

Why Choose Us

Changzhou JIER precision machinery manufacturing Co., Ltd is specializing in the production of various kinds of spray wire plate.We have introduced comprehensive domestic and foreign advanced spray wire plate. For years, through the production process ,technology process and high precision machining testing equipment continuously and automatically innovation and training, together with all staff meticulous work attitude, our spinneret manufacturing level completely meet your requirements of stringent quality of products .

Packing & Delivery

Packing Details : Packing, cardboard box or wooden case

FAQ

A: We are factory. And we can supply spinning packs according to your requirements.

A: Yes, we could offer the sample for extra charge and do not pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance after the goods have been manufactured. We will arrange the shipment after your payment.