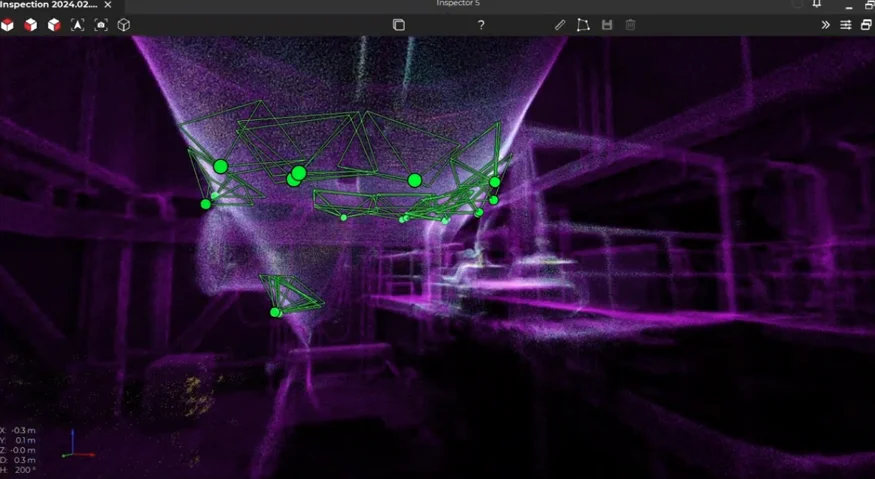

Accessibility With the Elios 3 UT, our team was able to enter the asset within mere minutes, while conventional methods would have taken at least a full day to set up and collect data. Speed Using the Elios 3 for inspections proved to be significantly faster than traditional approaches, allowing us to examine multiple large assets in a single day. Safety Employing a UT drone for inspections eliminates the need for scaffolding and rope access, minimizing risks to personnel.  Data Quality The Elios 3 collects precise UT spot measurements inside assets, meeting the high standards required for industrial inspections and supporting advanced digital asset management. A cement plant depends on seamless connectivity across all assets—from the quarry to the crusher, mills to the kiln, clinkers to silos. Proper maintenance of each component is meticulously planned by plant managers to reduce operational disruptions when any asset is partially or fully out of service. Inspections play a crucial role in maintaining the production efficiency of a cement plant. While visual inspections are often part of the broader non-destructive testing process, gathering ultrasonic thickness (UT) measurements is essential to monitor the condition of specific assets. However, accessing all these assets isn’t always straightforward. Scaffolding or rope access is frequently needed to reach higher structures, which is time-consuming and poses risks to workers. The Elios 3 and its UT payload offer a safer, more efficient inspection alternative today. The Elios 3 is a specialized UT drone designed to access complex and confined spaces without putting people in harm's way. By entering stacks or silos, the drone can gather critical data necessary for certifying asset conditions and identifying potential maintenance needs early. InspecDrone, a leading inspection company based in Germany, was involved in testing the new UT payload for the Elios 3 drone. During this project, they visited a cement plant to inspect assets and showcase to the site owners how the drone could revolutionize and improve their inspection processes. The first asset we inspected was a flue duct. This duct transitions from a rectangular shape at one end to a more rounded form further along. The initial rectangular section had been partially replaced, and the client wanted to assess the degradation of the remaining steel. Since this duct transports air and dust up to 300 degrees Celsius in temperature and is highly corrosive, its deterioration must be closely monitored. If it were to break, replacing it would be extremely challenging and could halt production for a significant portion of the plant. Inspecting this duct traditionally is quite challenging. Due to insulation on the structure and its bending shape, it must be inspected from the inside. Standing at 50 meters tall and equipped with a fan system, it only has one open end, severely limiting confined space inspections. Using people for such inspections would require opening the fan casing to meet confined space entry regulations, which adds complexity. A typical inspection involves a team of three or more people: one climbing with rope access, another supervising safety, and a third assisting the climber. Preparing ropes, safety protocols, and obtaining permits usually takes at least a day—if not longer—before data collection begins. As a result, inspecting even a small section of this flue duct proves daunting. The Elios 3 and its UT payload navigated through the flue duct despite dust and its complex shape With the Elios 3, everything became much simpler. The drone entered the duct and was guided by a single pilot through the targeted rectangular area. The entire inspection took less than two hours. For this type of inspection, it’s common to take five UT measurements per meter, plus additional spot measurements at key points of interest. Thanks to the Elios 3’s clear visual data, it was easy to pinpoint areas requiring extra attention. Over four flights inside the duct, the Elios 3 pilot collected over 20 measurements per flight, focusing on the first few meters inside the duct. The inspection conducted by InspecDrone was so swift that they were granted permission to perform demonstration UT inspections on other assets. The site managers, accustomed to traditional methods, were amazed by how quickly the Elios 3 UT completed the inspection, combining both visual and ultrasonic data. Next, the Elios 3 was tasked with inspecting the cones of limestone silos. These large steel structures were housed inside a warehouse. Without insulation, it was possible to take measurements from the outside of the silos. However, they were elevated several meters off the ground, complicating UT measurements as access would require scaffolding or mobile elevated work platforms. Despite the logistical challenges, these inspections are vital since the cones experience high abrasion rates. Conducting inspections of six silos using traditional scaffolding methods would likely cost several thousand euros, take hours of planning, and necessitate multiple measurement points per silo. Previous UT measurements had been noted with chalk markings on the silos, which is neither clear nor reliable for tracking changes in UT measurements. The Silo cones were inspected with the Elios 3 alongside existing chalk markings On the other hand, the Elios 3 with its UT payload completed UT surveys effortlessly. Within one to two flights per silo, the drone could measure 25-30 points. Just one pilot was needed, contrasting sharply with the labor-intensive process of scaffolding. Additionally, the Elios 3 UT provides results in a digital format that are geolocated onto the asset. This means there is a digital record not only of the UT measurement but also its exact location, enabling future inspections to use the same measurement points and simplify calculating the abrasion rate and monitoring the asset’s overall condition. Moreover, the Elios 3 pilot was given the opportunity to inspect ducts located in the roof of the building. These ducts are notoriously difficult to access, and are typically only maintained when something goes wrong, like an unusual noise or visual defect. Now, with the Elios 3, it’s possible to conduct a brief inspection and gain an overview of the condition of these smaller ducts. This data was previously unavailable, yet the Elios 3 UT was able to gather it in minutes, alongside the silo inspections and the flights inside the flue duct. The speed, safety, and enhanced access provided by the Elios 3 UT in a single day at this cement plant highlighted the immense impact this technology can have on inspection processes. Instead of relying on methods that involve extensive planning, special permissions, and prolonged downtime, the Elios 3 UT was able to collect data swiftly and safely. Quality of results: with the Elios 3 UT, it’s easy to localize and record UT points ready for analysis later in Inspector 5 Beyond this, the access provided by the drone can enhance the overall operation of the site. With quicker inspections, they can be performed more frequently and preemptively, rather than waiting until issues arise due to cost or downtime concerns. This marks a significant advancement in optimizing plant operations, offering long-term savings from using drones instead of one-time benefits. It opens the door to greater productivity without compromising safety or the integrity of the site. InspecDrone’s client was so impressed that they expressed interest in exploring the Elios 3 UT drone’s potential for inspecting other assets around the site. From the flue duct to the silos and the smaller duct systems, the Elios 3 demonstrated that inspections need not be cumbersome or complex—they can be swift without sacrificing the quality of data collected.  Renewable Energy Advances with Cast Film Lines New Energy Cast Film Line,Solar Energy Cast Film Machine,Photovoltaic Cast Film Machine,Plastic Film Perforation Machine Baijia Mechanical Equipment (Huizhou) Co., Ltd. , https://www.castfilmmachine.comUT Drone Inspections At A Cement Plant

Key Benefits At A Glance

Moving Toward Industrial UT Drone Inspections

Inspecting Assets Using The Elios 3 UT Drone

1. Flue Duct

2. Silo Cones

Expanding Inspection Possibilities With Drones

As the energy industry leans more towards renewable resources, solar energy emerges as a prominent option. Here is where "New Energy Cast Film Lines" play a critical role. They produce the specialized films used in solar technology, which are key in tapping into the sun's power.

The Importance of Plastic Films in Solar Systems

Solar setups often depend on plastic films. These essential components are made using machinery like the "Solar Energy Cast Film Machine" and the "Photovoltaic Cast Film Machine." The films created have unique characteristics, allowing them to turn solar energy into electrical power.

Let's take a closer look at two main film types

Photovoltaic Films: Found in the heart of solar cells, these films, primarily silicon-based, absorb sunlight and generate power thanks to the photovoltaic effect.

Backsheet Films: Acting as a shield, these films are placed on the rear of solar panels to protect against weathering, helping to ensure the panels' efficacy over time.

The Process Behind New Energy Cast Film Lines

Machines involved in this process, which include the indispensable "Plastic Film Perforation Machine," perform a procedure known as cast film extrusion. This involves melting plastic, shaping it into sheets that are then cooled, set, and rolled. These machines are carefully calibrated to output films with precise attributes suited to the solar energy industry.

Choosing Suitable Cast Film Line Equipment

Selecting a "New Energy Cast Film Line" requires a few considerations:

Material Choice: The type of plastic you use has implications for the film's overall performance and lifespan.

Quality of Film: Details like film thickness, light permeability, and strength need to be in tune with the intended solar applications.

Custom Features: Features such as film perforations can be added to enhance the functionality of the films, such as enabling the breathability of backsheet films to reduce moisture buildup.

Embracing a Green Energy Future

With "New Energy Cast Film Lines," we're not just investing in equipment. We're taking strides towards a greener, more sustainable energy landscape by producing essential components for solar technology, furthering the progress in the realm of renewable energy.