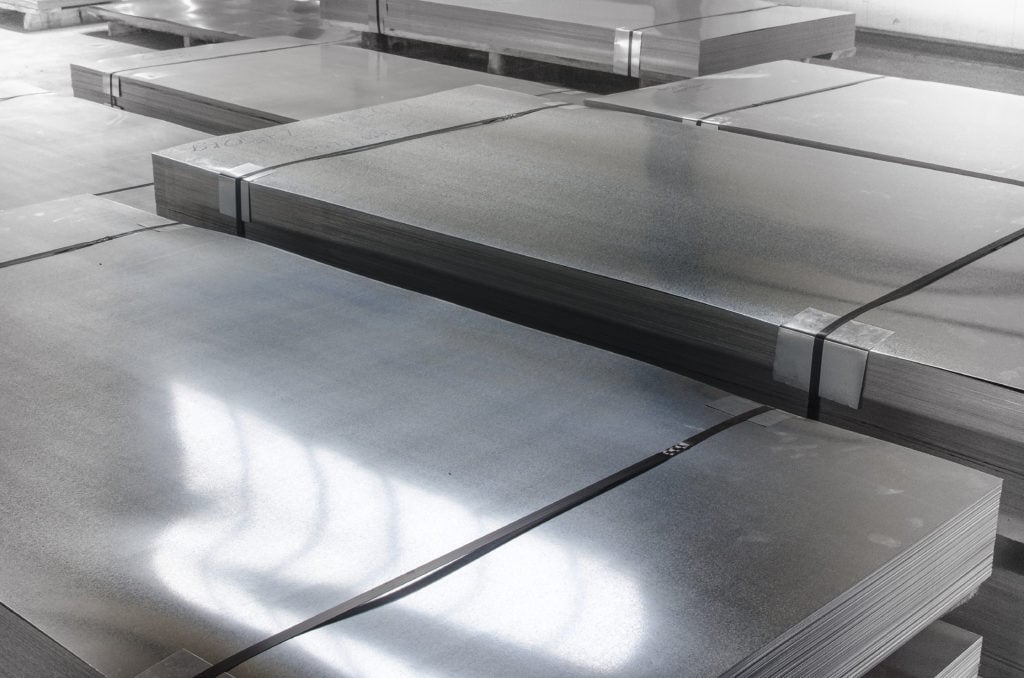

Throughout 2021, the market has witnessed a sharp increase in the prices of steel, stainless steel, copper, and other commonly used base metals. This has been a challenging time for manufacturers who rely heavily on these materials. Fortunately, ESI has developed strategies to manage market volatility, allowing us to provide sustainable and cost-effective metal solutions for our clients. Our extensive experience working with various metals has given us valuable insights into how fluctuating prices can impact overall business operations. A recent article in the New York Times highlighted that prices for steel, stainless steel, aluminum, and copper are at record levels. There are several key factors driving these increases during our post-COVID economic recovery: In recent years, the U.S. has imposed tariffs to reduce imports of materials, which has already started pushing prices upward. Companies involved in steel and other metal production are being encouraged to consolidate and bring operations back to the U.S. Meanwhile, aluminum importers face shortages from Canada, and there's fierce competition for copper and nickel in the energy storage and electric vehicle sectors. This presents an opportunity to create significant job growth within the American economy.

This reshoring initiative gained momentum in 2020 due to the pandemic, and despite ongoing freight shipping challenges and truck driver shortages, some tariffs remain in place, leading to further price hikes. Supply chain disruptions worsened throughout the pandemic, resulting in raw material shortages for companies ramping up production in a recovering economy. Freight shipping costs have reached all-time highs, with China’s ten largest ports experiencing a staggering 126% increase in D&D charges, according to industry reports. These supply chain issues aren’t limited to overseas markets; truck driver shortages exacerbated by the pandemic and the surge in e-commerce are causing longer lead times and what Uber Freight’s logistics head refers to as a "shipping Armageddon."

The above trends have led to a situation where demand for materials exceeds supply, making it difficult to provide accurate pricing and lead times for manufacturing projects. As industries continue to adapt to these supply chain issues and scale up production during the post-COVID recovery, demand for metal products is expected to remain strong. Additionally, the push for clean technology in renewable energy and renewed infrastructure investments in the U.S. and China are contributing to the perfect storm of high metal prices. While nearly every metal market is feeling the pinch of supply shortages and high demand, those most commonly used in industrial production are the hardest hit. Manufacturers should anticipate significant increases in steel, aluminum, copper, and nickel.

How to Select the Right Material for Your Stamped Metal Part: Learn more here Although forecasts predict that metal prices will eventually decrease as the global economy recovers, they are unlikely to return to pre-pandemic levels anytime soon. The market is expected to remain tight well into 2022, with large-scale infrastructure projects in the U.S. and China sustaining high demand for these metals.

The pandemic is having a broader impact than just price increases, as shipping challenges may lead to extended lead times for certain materials. Given the current tight supply, we recommend adding several months or more to your production lead times in 2022. Due to sourcing uncertainties, lead times for many projects have been pushed back. It’s crucial for your planning to understand how the metal materials in your project might affect both turnaround times and costs—our team at ESI can assist with that.

To stay ahead, ESI is overcommitting resources to ensure we have the necessary materials for upcoming projects. Our long-standing relationships with metal suppliers over the last 30 years keep us informed about market trends, enabling us to offer insights into alternative designs and materials that could yield better costs or faster delivery without compromising your project requirements.

Regardless of market conditions, our metal experts at ESI strive to maintain competitive pricing for our clients. We closely monitor metal costs and trends to guarantee your project is completed in the most cost-effective way possible. For more information on pricing for our metal products and services, reach out to us today!

Wuxi Changchen Technology Co., Ltd , https://www.wxchangchen.com

Why Are Metal Prices Rising?

1. Tariffs and reshoring efforts.

2. Pandemic-related transportation disruptions.

3. Global capacity challenges.

Which Metals Are Most Affected?

When Will Prices Drop?

Stay Competitive with Cost-Effective Metal Products from ESI

Comments are closed