Building and maintaining roads is a complex and essential task that requires precision at every stage. One of the most important steps in road rehabilitation is milling, a process that removes the top layer of existing pavement to prepare the surface for new asphalt. This is done using specialized road milling machines, which are designed to efficiently and accurately strip away old materials. In this post, we’ll explore everything you need to know about road milling—its benefits, how it works, and how to choose the right machine for your project. What is Milling in Road Construction? Milling, also known as cold planing, is a key process in road construction where the top layer of asphalt is removed to create a smooth, even surface for new paving. This method ensures that the new layer of asphalt is applied correctly without increasing the height of the road. By eliminating worn or damaged material, milling not only prepares the surface for resurfacing but also helps maintain the original design and structural integrity of the road. It's a crucial step in both repair and renewal projects. Milling offers numerous benefits that make it an essential technique in modern road maintenance and construction. Here are some of the main advantages: The milling process involves large, powerful machines equipped with a rotating drum that grinds and removes the existing pavement. These machines can adjust their depth and width based on the specific needs of the project. Operators control the speed and rotation of the drum to ensure even and precise removal of the asphalt layer. This technique not only clears the surface but also creates a stable base for the new layer of asphalt to be laid on top. SANY India is a globally recognized leader in construction machinery, known for its innovation and reliability. Our range of road milling machines is designed to meet the toughest demands of modern road construction. Among our popular models, the SCM1000C-8, SCM1300C-8, and SCM2000-8S stand out for their performance, durability, and efficiency. Selecting the right road milling machine is crucial for the success of your construction projects. Understanding the process and choosing a reliable, high-performance machine like those from SANY India can significantly improve efficiency, accuracy, and cost-effectiveness. Whether you're working on small repairs or large-scale road projects, the SCM1000C-8, SCM1300C-8, and SCM2000-8S models are excellent choices that deliver proven results. Invest in quality equipment today and achieve better outcomes on your next road project. Forged Parts,Aluminum Forged Parts,Forged Components,Cold Forged Components Suzhou SNK Machinery Equipment Co.,LTD , https://www.snkforging.com

Advantages of Milling in Road Construction

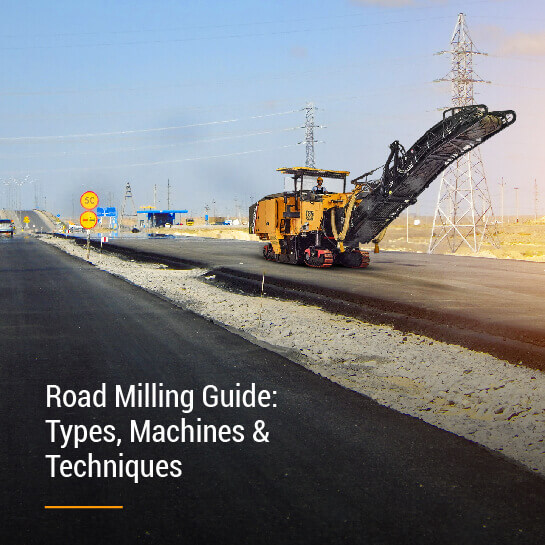

How is Milling Done?

Key Factors to Consider When Buying a Road Milling Machine

SANY India – Leading Road Milling Machines

In Summary