Building and maintaining roads is a complex and essential process that demands precision at every stage to ensure safety, durability, and long-term performance. One of the most critical steps in road construction is milling—a technique used to remove the top layer of old pavement before applying new asphalt. This task is carried out by specialized machines designed for efficiency and accuracy. In this post, we’ll walk you through everything you need to know about road milling, including its benefits, how it’s done, and how to choose the best machine for your project. What is Road Milling? Road milling, also known as cold planing, is a key process in road construction where the top layer of existing asphalt is removed. This method is essential for preparing the surface for new materials, ensuring that the addition of new layers doesn’t raise the overall height of the pavement. By eliminating worn or damaged asphalt, milling creates a smooth and even base for new layers to be applied. This not only improves the appearance of the road but also ensures proper adhesion between the old and new surfaces, which is crucial for the road’s structural integrity. Milling offers numerous advantages that make it a preferred choice for road maintenance and rehabilitation. Here are some of the main benefits: The milling process involves the use of heavy-duty road milling machines equipped with a rotating drum fitted with cutting teeth. These machines grind and remove the top layer of pavement, typically ranging from 1 inch to several inches deep, depending on the project's needs. Operators control the machine’s speed and depth to ensure even removal and optimal performance. This process not only prepares the surface for new asphalt but also helps maintain the original grade and alignment of the road. SANY India is a leading name in the construction machinery industry, known for its innovative and reliable equipment. Our range of road milling machines is designed to deliver high performance and durability, making them ideal for a wide range of road construction and maintenance projects. We offer several models tailored to meet the specific needs of different applications. Choosing the right road milling machine can significantly impact the success of your construction projects. Whether you're working on a small repair or a large-scale road development, investing in quality equipment like SANY India’s SCM series ensures efficiency, precision, and long-term value. By understanding the milling process and selecting the right machine, you can achieve better results and reduce costs. Explore our range today and take your road projects to the next level. Forged Shaft,Hollow Shaft,Shaft Forging Part,Stainless Steel Shaft Suzhou SNK Machinery Equipment Co.,LTD , https://www.snkforging.com

The Benefits of Road Milling

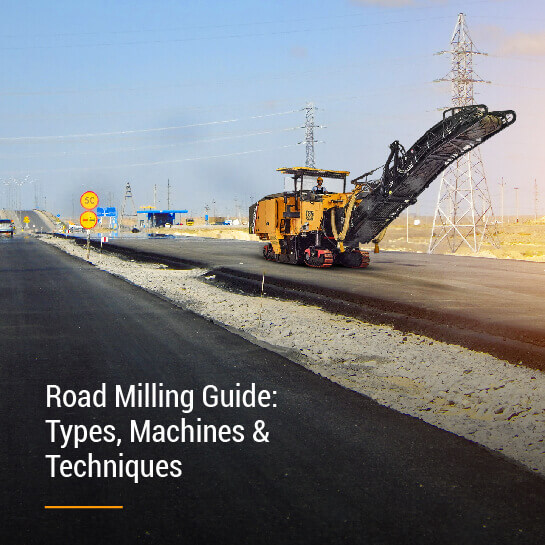

How Does Road Milling Work?

Key Features to Consider When Buying a Road Milling Machine

SANY India – Leading Road Milling Machines

In Summary