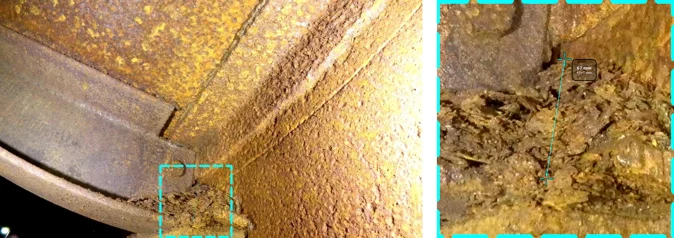

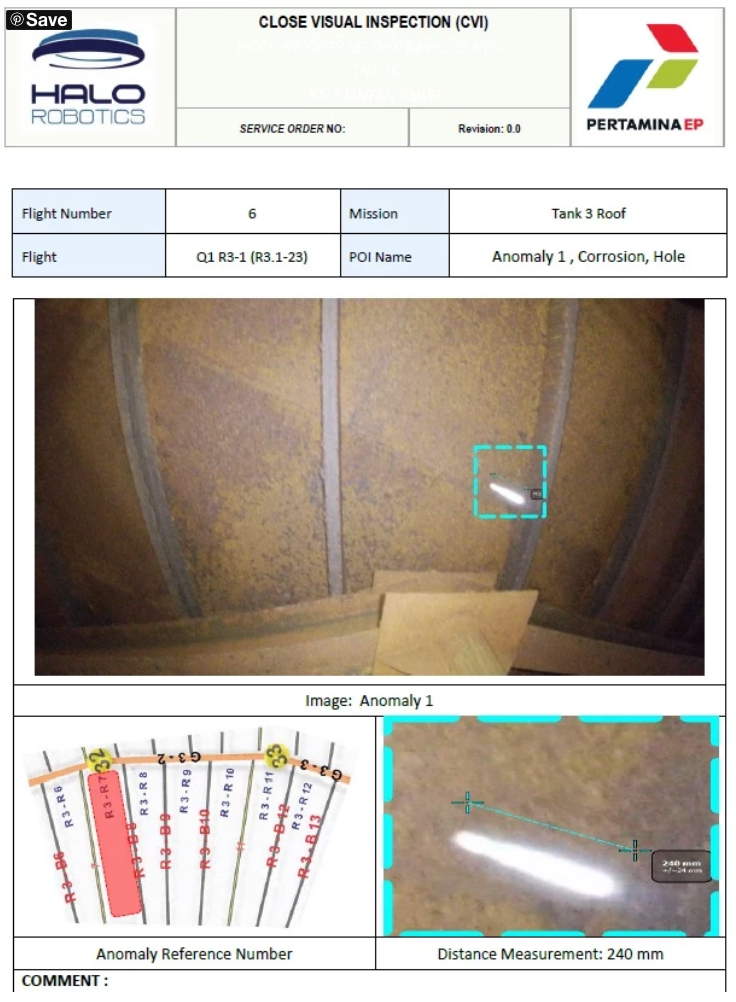

Pertamina, Indonesia's leading energy company, partnered with Halo Robotics to perform a major overhaul of a large crude oil storage tank. The Elios 2 drone was deployed for the inspection, delivering results that exceeded all expectations. Safety: By using the Elios 2 to collect visual data inside the tank, the need for human entry via rope access or scaffolding was eliminated, significantly improving worker safety during the inspection process. Return on Investment: The use of the Elios 2 reduced inconsistencies between asset owners and EPC contractors, resulting in cost savings from reduced downtime and the elimination of expensive scaffolding setups. Efficiency: The drone enabled a more streamlined and systematic approach to tank inspections, allowing for repeatable assessments of aging infrastructure over time, which is crucial for long-term maintenance planning. Data Coverage: The Elios 2 provided access to previously unreachable areas, capturing high-quality visual and thermal data quickly and comprehensively. This enhanced the overall quality of the inspection and allowed teams to gather more detailed insights than ever before. Pertamina is Indonesia’s national energy company and one of the country’s most important players in the oil and gas sector. To enhance its maintenance processes, Pertamina partnered with Halo Robotics, a Jakarta-based drone technology firm, to assist with a major maintenance project at one of its refineries in Balongan, Indonesia. The refinery has a capacity of 125 mbsd (Thousand Barrels per Stream Day). The specific asset requiring attention was a massive crude oil storage tank. This tank shares many design features with API 650 tanks, which are commonly used worldwide for storing crude oil and gasoline. As a result, the methods and outcomes of this project could be applicable to similar facilities across the globe. A picture of the oil storage tank at the Balongan refinery Pertamina needed to conduct a comprehensive inspection of a large crude oil storage tank at its Balongan refinery. The tank, built in 1972, had a capacity of 37,000 cubic meters and was in need of significant maintenance. The main objectives of the project included updating outdated 1972 drawings with current schematics, conducting a thorough internal inspection to determine EPC requirements, reducing the risks associated with manual entry into confined spaces, and improving the efficiency of EPC processes. A key requirement was ensuring that the data collected could be used effectively across all stages of the maintenance process, including engineering, procurement, and construction. To achieve these goals, Pertamina divided the work into two main outputs: The ultimate goal was to establish a scalable process that could be applied across PERTAMINA’s nationwide operations. This case study focuses on the second output—confined space inspection. For details on the digital twin creation, refer to the full white paper on Halo Robotics’ website. Inspectors working inside the oil storage tank Halo Robotics was tasked with implementing new technologies to support both outputs of the project. For the confined space inspection, they chose Flyability’s Elios drone due to its advanced capabilities, including: A picture of the Elios 2 flying in the oil storage tank during the drone tank inspection. The Elios 3 now provides LiDAR and close visual data during flights. The Elios 2 performed exceptionally well during the confined space inspection, surpassing expectations in terms of safety, speed, and data quality. Compared to traditional methods that required manual entry with ropes and scaffolding, the drone offered a safer, faster, and more efficient solution. "The results achieved through this drone technology exceeded our expectations. These operations will greatly support preventive maintenance by helping us identify defects, plan the right maintenance, and improve speed and accuracy," said Almuayat Librata, Oil and Gas Transportation Manager at Pertamina EP. Halo Robotics created detailed flight plans to inspect various parts of the tank, including the shell, welds, rafters, girders, joints, and roof. Over five days, 20–22 flights were conducted daily using the Elios 2, resulting in a total of 760 GB of video footage (including 4K RGB and thermal video). This data was processed offsite using Flyability’s Inspector software to generate a formal inspection report. The software allowed for easy review of large volumes of footage, selection of Points of Interest (POIs), and annotation of findings. Thermal video was also overlaid on RGB footage for comparative analysis. The entire process, from data collection to final report generation, took 14 days, including a detailed review by an API-certified inspector. Corrosion Identified – Tank Joint Left Side Inspector comments: Flaking and Oil Material Build-Up Observed – Tank Joint Right Side Inspector comments: Example report generated by Flyability’s Inspector software The success of this project marked a turning point for Pertamina. The Elios 2 demonstrated that even the largest oil storage tanks can be systematically inspected using drones, eliminating the need for dangerous and costly manual entry. "We believe that implementing this type of drone technology will significantly improve tank inspections by reducing risk and costs while making the process safer and more efficient," said Erikson Nainggolan, Operation Planning Assistant Manager at Pertamina EP. With this successful project behind them, Pertamina is now exploring how to expand the use of drone technology across other maintenance projects at its refineries throughout Indonesia. The future of tank inspections is clearly moving toward automation, precision, and safety. Dry Foam Brick,Floral Foam For Artificial Flowers,Dry Foam For Artificial Flowers,Dry Floral Foam Bricks SHANGHAI WELLONG IMPORT AND EXPORT CO., LTD , https://www.chinafloralfoam.comDrone Tank Inspections: Oil Storage Tank Inspection Sees Improved Safety, Cost, and Efficiency

Key Benefits at a Glance

Introduction

Innovating Oil Storage Tank Inspections

Using the Elios for Drone Tank Inspections

Gathering Visual Data During a Drone Tank Inspection

Drone Tank Inspection Mission Details

Point of Interest (POI) Reporting Examples

Looking Ahead to Drone Tank Inspections