Chongqing Huanyu Automobile Sales Company , https://www.huanyuauto.com

In the dynamic realms of metalworking and woodworking, precision and efficiency stand as the cornerstones of success. Among the tools that have revolutionized these industries, bandsaw machines have emerged as a quintessential choice for sectors spanning construction, automotive, aerospace, and manufacturing. Known for their adaptability, accuracy, and ease of use, bandsaw machines have become an essential fixture in any professional workshop. Whether you opt for a semi-automatic or fully automatic model, these machines consistently deliver high-quality cuts with minimal effort.

This article delves into the functionality, advantages, and applications of bandsaw machines, with a particular emphasis on double-column semi-automatic variants and their pivotal role in boosting productivity within contemporary industries.

### Understanding the Bandsaw Machine

A bandsaw machine is a powerful tool that employs a continuous loop of metal blade with teeth on one side to cut through a variety of materials, including metals, wood, and plastics. The blade moves on two or more wheels, enabling it to make precise cuts with a narrow kerf, which helps minimize material wastage.

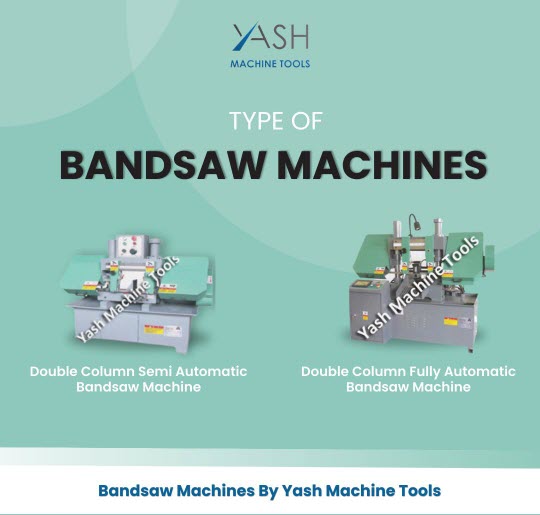

Bandsaw machines come in diverse configurations, ranging from manual to fully automatic models. Depending on the specific requirements of your industry, these machines are available in varying sizes and designs, making them suitable for an extensive array of cutting tasks.

### The Significance of Double-Column Semi-Automatic Bandsaw Machines

Among the most popular bandsaw machines are the double-column semi-automatic models. Renowned for their strong build and superior performance, especially in metal cutting, these machines have gained popularity in industries where precision and consistent cuts are vital. Their design and operational efficiency make them ideal for sectors requiring exacting standards.

#### 1. Enhanced Blade Life for Superior Performance

In a double-column semi-automatic bandsaw machine, the blade is engineered to ensure optimal performance. The machine's structure and mechanisms evenly distribute pressure across the blade, reducing wear and tear. This prolongs the blade's lifespan, which not only lowers maintenance costs but also improves operational efficiency.

For industries that depend on nonstop production, frequent blade changes can disrupt workflow and increase downtime. By improving blade performance, double-column semi-automatic bandsaw machines ensure seamless production and uninterrupted operations.

#### 2. Advanced Technology for Precision Cutting

The latest technological advancements are integrated into the design and operation of semi-automatic bandsaw machines, particularly those with a double-column framework. These machines incorporate sub-functions that have been meticulously analyzed and implemented to enhance cutting accuracy. The high-end technology employed guarantees each cut meets the highest quality standards, fulfilling the stringent requirements of industries such as automotive, aerospace, and construction.

The cutting accuracy provided by these machines ensures clean cuts with minimal deviation from the desired dimensions. This is crucial in industries where precise component dimensions are essential for final assembly.

#### 3. High Levels of Automation for User-Friendly Operation

Semi-automatic bandsaw machines automate key functions such as material capacity, feeding, and positioning. This reduces the need for manual intervention, increasing efficiency and minimizing the risk of human error. Operators can set the necessary parameters, and the machine handles the rest.

By automating critical functions, these machines ensure consistent and repeatable cuts, vital for maintaining quality in large-scale production. The automation of feeding and positioning reduces operator fatigue, enabling higher production rates even in demanding environments.

#### 4. Robust Construction for Durability

Bandsaw machines, particularly those from reputable suppliers, are known for their robust and durable construction. Designed to withstand the rigors of continuous use, these machines are suitable for heavy-duty applications. Whether cutting hard metals or dense woods, the sturdy construction of double-column bandsaw machines ensures long-lasting performance.

The solid construction not only enhances longevity but also contributes to stability during operation. This stability is essential for achieving accurate cuts, especially when handling large or heavy materials. As a result, bandsaw machines from trusted manufacturers are globally recognized for their reliability and durability.

#### 5. Seamless Operation for Reduced Hassle

One of the major advantages of bandsaw machines, particularly those from top suppliers, is their ability to offer hassle-free operation. Due to their advanced design and high-quality components, these machines require minimal maintenance and provide consistent performance over extended periods.

For industries where downtime can lead to significant losses, having a machine that operates smoothly is crucial. The dependable performance of bandsaw machines reduces the frequency of repairs and replacements, ensuring production schedules remain intact without costly interruptions.

### Benefits of Utilizing Bandsaw Machines

Having explored the features of double-column semi-automatic bandsaw machines, let’s examine the broader advantages of using bandsaw machines in general.

#### 1. Versatility in Cutting

One of the standout traits of bandsaw machines is their versatility. They can cut a wide range of materials, including metals, wood, plastics, and composites. Whether you're cutting soft materials like aluminum or tough ones like stainless steel, bandsaw machines handle the task effortlessly.

The ability to switch between different materials without sacrificing precision makes bandsaw machines invaluable in industries dealing with multiple material types in their production processes.

#### 2. Precise Cuts with Minimal Material Loss

Bandsaw machines are designed to make highly precise cuts thanks to their narrow blades. The narrow kerf produced by these machines ensures minimal material wastage during the cutting process. This precision is especially important in industries where expensive materials are used, as reducing waste can lead to significant cost savings over time.

In sectors like aerospace or high-end manufacturing, where material costs are high, the precision and efficiency of bandsaw machines are essential for optimizing material usage and reducing expenses.

#### 3. Increased Production Efficiency

The combination of automation and precision in bandsaw machines significantly boosts production efficiency. Semi-automatic models, in particular, allow for continuous operation with minimal manual intervention. This results in faster production cycles, as the machine can operate for longer periods without the need for frequent adjustments or recalibrations.

In high-volume production settings, this increased efficiency translates into higher output, enabling manufacturers to meet tight deadlines without compromising on quality.

#### 4. Reduced Operator Fatigue

With semi-automatic bandsaw machines, much of the manual labor involved in material positioning and feeding is eliminated. This reduces the physical strain on operators, allowing them to focus on monitoring the machine’s performance instead of performing repetitive tasks. The reduction in manual labor not only improves operator comfort but also minimizes the likelihood of errors, leading to higher-quality results.

The ergonomic design of modern bandsaw machines ensures that operators can work for extended periods without experiencing fatigue, which is crucial in industries with demanding production schedules.

#### 5. Cost-Effectiveness Over Time

Although the initial investment in a high-quality bandsaw machine may seem significant, the long-term benefits far outweigh the costs. The durability and low maintenance requirements of these machines ensure years of reliable service with minimal downtime. Additionally, the reduction in material waste and increased production efficiency contribute to lower operating costs over time.

For industries focused on long-term profitability, investing in a high-quality bandsaw machine is a wise decision that offers substantial returns in terms of productivity and cost savings.

### Applications Across Industries

Bandsaw machines are widely utilized across various industries due to their versatility and precision. Key applications include:

- **Metalworking**: Commonly used in metal fabrication shops for cutting steel, aluminum, and brass.

- **Woodworking**: Employed in woodworking shops to make precise cuts in lumber, plywood, and other wood-based materials.

- **Automotive**: Used in the automotive industry to cut components like engine parts, chassis pieces, and brackets.

- **Construction**: Also used in construction for cutting materials like steel beams, pipes, and rebar.

### Conclusion

Bandsaw machines, particularly double-column semi-automatic models, offer a host of benefits that make them indispensable in modern manufacturing environments. From their optimized blade life and advanced technology to their robust architecture and hassle-free performance, these machines are tailored to meet the demands of today’s high-precision industries. Investing in a bandsaw machine is not just a purchase—it’s a commitment to excellence and efficiency.