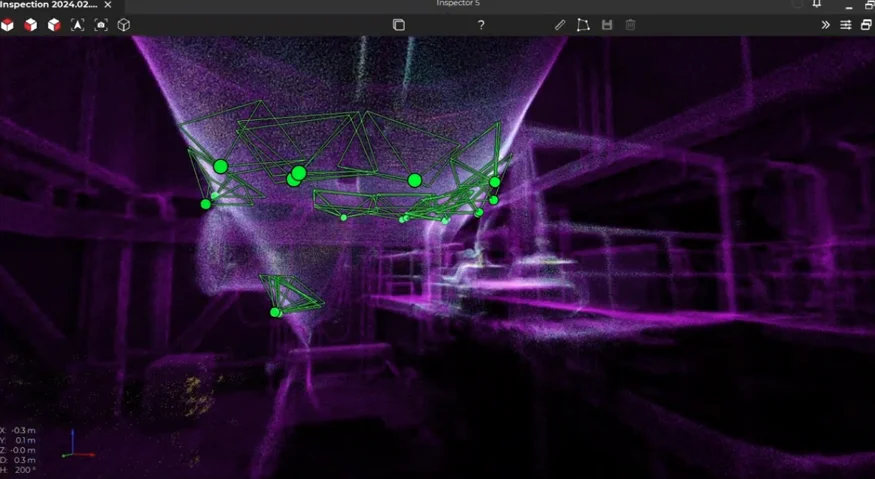

Accessibility Speed Thanks to the Elios 3, inspections were significantly faster than traditional methods, allowing us to assess multiple large assets in a single day. Safety Utilizing a UT drone for inspections eliminates the need for scaffolding and rope access, thereby reducing the risks to personnel.  Data Quality The Elios 3 collects precise UT spot measurements inside assets, meeting the standards required for industrial inspections and enabling better digital asset management. A cement plant relies heavily on seamless connectivity between assets—from the quarry to the crusher, mills to the kiln, clinkers to silos. Each element of this process requires meticulous maintenance by plant managers to minimize operational disruptions when an asset is unavailable. Inspections play a crucial role in maintaining the production efficiency of a cement plant. While visual inspections are essential, gathering ultrasonic thickness (UT) measurements is equally important to monitor the condition of specific assets. However, accessing all these assets isn't always straightforward. Often, scaffolding or rope access is needed to reach higher structures, which is time-consuming and poses risks to staff. The Elios 3 and its UT payload offer a safer, more efficient alternative for inspections. The Elios 3 is a specialized UT drone designed to access complex and confined spaces instead of requiring human intervention, reducing staff risk exposure. By entering structures like stacks or silos, the drone can collect vital data needed to certify asset conditions and identify maintenance needs early. InspecDrone, a German inspection company, tested the new UT payload for the Elios 3 drone. During this trial, they visited a cement plant to inspect assets and demonstrate to the site owners how the drone could streamline and improve inspections. The first asset being inspected was a flue duct. This duct transitions from a rectangular shape at one end to a more rounded form further along. The rectangular section had been partially replaced, and the client aimed to assess the degradation of the remaining steel. Since this duct transports air and dust up to 300 degrees Celsius in temperature and corrosive conditions from the raw mill to a filter, monitoring its condition is critical. If it were to fail, replacing it would be extremely challenging and could halt production for a significant portion of the plant. Conventional methods of inspecting this duct are highly challenging due to its insulation and bending design. It measures 50 meters in height and has only one open end due to a fan system. This makes confined space inspections with people nearly impossible without opening the fan casing to comply with safety regulations. Typically, such inspections require a team of three or more people, including a rope-access climber, a safety observer, and an assistant. Preparing ropes, conducting safety checks, and obtaining permits often takes at least a day, if not longer—before any data is collected. Thus, even inspecting a small section of this flue duct is a daunting task. The Elios 3 and UT payload navigated the flue duct, overcoming challenges posed by dust and bends. With the Elios 3, this process became far simpler. The drone easily entered the duct and flew through the targeted rectangular area under the guidance of just one pilot. The entire inspection took less than two hours. For this type of inspection, it is standard practice to take five UT measurements per meter, in addition to extra spot measurements at points of interest. Thanks to the Elios 3's clear visual data, it was simple to identify areas needing additional A-scans. Over four flights inside the duct, the Elios 3 pilot collected over 20 measurements per flight, examining the first few meters inside the duct. The inspection by InspecDrone was so swift that they were granted permission to perform demonstration UT inspections on other assets. The site managers, accustomed to traditional methods, were astounded by how quickly the Elios 3 UT completed the inspection, providing both visual and ultrasonic data. The Elios 3 was then tasked with inspecting the cones of limestone silos. These large steel structures were housed inside a warehouse, with no insulation, making it possible to take measurements from the outside. However, they stood several meters off the ground, complicating access for UT measurements, which would require scaffolding or mobile elevated work platforms. Despite the logistical challenges, inspecting these cones is crucial because of their high abrasion rates. Using traditional scaffolding to inspect all six silos would likely cost several thousand euros, involve hours of planning, material transport, and numerous measurement points per silo. Previous UT measurements had been recorded with chalk markings on the silos, but this method lacks clarity and reliability. The Silo cones were inspected with the Elios 3 alongside the existing chalk measurements. On the other hand, the Elios 3 with its UT payload completed UT surveys effortlessly. Within one to two flights per silo, the drone measured 25-30 points. All of this was achieved by just one pilot, in stark contrast to the labor-intensive scaffolding process. Furthermore, the Elios 3 UT provides digital results that are geolocated onto the asset. This means there is a clear digital record of not only the UT measurement but also its exact location, allowing future inspections to use the same measurement points and simplify calculating abrasion rates and monitoring the asset's condition. In addition, the Elios 3 pilot had the opportunity to inspect ducts located in the roof of the building. These ducts are difficult to access and are usually only maintained when a problem arises, such as unusual noises or visible defects. With the Elios 3, it became possible to conduct a brief inspection and obtain an overview of the condition of the smaller ducts. This information was previously unavailable, yet the Elios 3 UT was able to gather it in minutes, alongside the silo inspections and flights inside the flue duct. The speed, safety, and enhanced access provided by the Elios 3 UT during a single day at this cement plant highlighted the immense impact this drone can have on inspection processes. Instead of relying on methods that require days of planning, special permissions, and extended downtime, the Elios 3 UT was able to gather data quickly and safely. Quality of results: with the Elios 3 UT, it is easy to locate and record UT points ready for analysis later in Inspector 5. Beyond this, the access provided by the drone can enhance the overall functioning of the site. Since inspections can now be conducted more swiftly, they can be performed preemptively, rather than less frequently due to cost or downtime concerns. This marks a significant leap forward in optimizing plant operations, offering long-term savings rather than one-time benefits. It opens a pathway to increased productivity without compromising safety or asset integrity. InspecDrone's client was so impressed that they expressed interest in learning more about how the Elios 3 UT drone could be applied to inspect other assets around the site. From the flue duct to the silos and the smaller duct systems, the Elios 3 demonstrated that inspections don’t have to be cumbersome or complex—they can be swift without sacrificing data quality.  Delving Into Automotive Cast Films and Production Technology Automobile Cast Film Line,Car Cast Film Line,Auto-Casting Film Machine,Multi Functional Stretching Film Machine Baijia Mechanical Equipment (Huizhou) Co., Ltd. , https://www.castfilmmachine.comUT Drone Inspections at a Cement Plant

Benefits In A Nutshell

Moving Towards UT Drone Inspections in Industry

Inspecting Assets with the Elios 3 UT Drone

1. Flue Duct

2. Silo Cones

Opening the Door to Improved Inspections with Drones

The vehicles we drive are marvels of not just engineering, but also material science. At the core of these material innovations are "Automobile Cast Film Lines," which are critical systems used for producing the specialized films found in various car components, enhancing both aesthetics and functionality.

Where Cast Films Make a Difference in Your Car:

In the realm of automotive design and safety, cast films have several applications

Interior Films: Look inside your vehicle at the dashboard, door panels, or other trim elements and you'll likely find films made from durable materials like polypropylene (PP) or ABS (Acrylonitrile Butadiene Styrene). These provide a surface that's resilient to daily wear and tear and customizable in appearance to fit vehicle aesthetics.

Functional Films: Move to the engine compartment and you'll see cast films in parts such as air ducts and radiator grilles. These are often designed to be heat resistant or flame retardant, contributing to the overall safety of the vehicle.

Protective Films: As an optional upgrade, paint protection film is applied to a vehicle's exterior to safeguard the paint-shielding it from minor scratches, harmful UV rays, and other environmental factors.

Crafting Cast Films for the Automotive Industry:

"Automobile Cast Film Lines," also known under names like "Car Cast Film Line" and "Auto-Casting Film Machine," operate through a process known as cast film extrusion. In this process, plastic material is melted, shaped into a continuous wide and thin layer, cooled, and then neatly rolled. These lines may sometimes involve additional equipment, such as a "Multi Functional Stretching Film Machine," which allows for the film's properties to be finely tuned for specific requirements.

Choosing the Best Cast Film Line for Production

When considering an "Automobile Cast Film Line" for manufacturing needs, keep in mind:

Type of Film: Different car parts require films with varying material compositions and thus different production setups. For instance, lines for making PP interior films are distinct from those making films for the heat-exposed engine area.

Film Characteristics: Important properties like film thickness, strength, and the desired finish must align with the car part it's destined for.

Production Capacity: The capacity of the "Automobile Cast Film Line" should match your projected production volume to ensure efficiency and supply demands are met.

Advancements in Cast Film Production and Future Outlook:

The industry producing automotive films is constantly advancing. "Automobile Cast Film Lines" are evolving with a focus on lighter, more sustainable materials and adding innovative features. Gaining insight into how these machines, such as the "Auto-Casting Film Machine," create different types of films deepens our understanding of the complex details behind the car components we often take for granted.