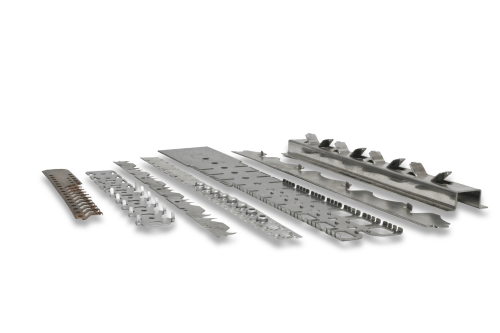

Progressive die stamping is a highly efficient manufacturing process used to create complex and durable metal parts. It involves feeding a continuous strip of metal through a sequence of workstations, each performing specific operations such as cutting, bending, or forming. This method allows for the high-speed production of consistent, high-quality components across various industries, from automotive to medical devices. The progressive die stamping process typically includes four main stages: Explore our in-house tool and die manufacturing capabilities Each stage of the progressive die stamping process is designed to meet ultra-high tolerance standards, ensuring consistent quality and performance. Let’s take a closer look at how these parts are created step by step. The process begins with the design of the progressive die using advanced computational modeling. Engineers optimize the layout of punches, bends, and holes on the metal strip to ensure accuracy and efficiency throughout the stamping cycle. Once the design is finalized, CNC machining is used to create the die blocks with exact specifications. These components undergo rigorous quality checks before being used in production, ensuring long-lasting performance and precision. Parts are strengthened through heat treatment, which enhances their durability and dimensional stability. Afterward, grinding may be applied to achieve even greater precision and surface finish. Wire Electrical Discharge Machining (EDM) is used to shape the die blocks with extreme precision. This technique can produce intricate shapes with tolerances as tight as ±2 µm and surface finishes as smooth as Ra 0.1 µm. After all components are machined, the die is assembled by engineers using precision tools. This ensures that the final product meets the original design specifications and maintains high performance over time. The completed die is installed in a stamping press. As the metal strip moves through the die, each operation adds to the next, resulting in the final shape of the part. This process ensures high-speed, high-volume production with consistent quality. Once the parts are stamped, they are packaged using automated systems that ensure accurate counts and weights for each order. This streamlines logistics and improves overall efficiency. Many industries rely on progressive die stamping for mass production of essential components. From appliances and automotive parts to medical devices and plumbing supplies, this method enables fast, cost-effective, and reliable manufacturing. Discover more about the differences between progressive, fourslide, and traditional power press stamping At ESI, we’ve helped numerous clients improve their manufacturing processes by creating and refining critical components. Here are a few examples of our successful projects: With over thirty years of experience in metal stamping, assembly, and mission-critical parts, ESI continues to invest in new technologies to deliver superior quality and cost savings. Whether you need custom tooling or large-scale production, we’re here to help. Contact us today or request a quote to learn how we can support your tool and die-making needs. We’re excited to work with you and bring your vision to life. H-beam Heavy Duty Production Line As a highly automatic H-beam

production line, Heavy-duty steel production line sees reducing the use

frequency of overhead crane as its subject. Through using automatic machines as

roller conveyor, turning machine and conveying machine to conveying, turning

and moving H beam during welding process, which greatly improved user`s production

efficiency. H-Beam Heavy Duty Production Line,Heavy Duty Weed Wacker Line,Heavy Duty Professional Line,Heavy Duty Production Line Wuxi Zhouxiang Complete Set of Welding Equipment Co., Ltd. , https://www.beamweldingmachine.com

Understanding the Progressive Die Stamping Process

How Parts Are Made with Precision

Stock Strip Layout & Design

Tool Steel and Die Set Machining

Secondary Processing: Grinding & Heat Treating

Wire EDM

Die Assembly

Stamping the Parts

Packaging and Shipping

Industries That Benefit from Progressive Die Stamping

ESI’s Progressive Die Stamping Services

Comments are closed